Internal combustion engines are the heart of many modern machines, from cars to generators. Among the various types of engines, 4-stroke engines are the most widely used due to their efficiency, reliability, and versatility. The 4-stroke engine's popularity can be attributed to its ability to provide a smooth and consistent power output, making it an ideal choice for a variety of applications.

In this article, we will delve into the inner workings of 4-stroke technology, exploring its history, components, working principles, and benefits. We will also examine the different types of 4-stroke engines and their applications.

History of 4-Stroke Technology

The 4-stroke engine has its roots in the late 19th century, when Nikolaus August Otto invented the first practical 4-stroke internal combustion engine in 1876. Otto's design used a combination of four strokes - intake, compression, power, and exhaust - to generate power. The 4-stroke engine quickly gained popularity due to its efficiency and reliability, replacing the earlier 2-stroke engines in many applications.

Components of a 4-Stroke Engine

A 4-stroke engine consists of several key components that work together to generate power. These components include:

- Cylinders: The cylinders are the chambers where the fuel-air mixture is ignited to produce power. The cylinders are typically arranged in a line or in a V-shape, and the number of cylinders can vary depending on the engine's application.

- Pistons: The pistons move up and down inside the cylinders, driven by the explosive force of the fuel-air mixture. The pistons are connected to the crankshaft, which converts the up-and-down motion into rotary motion.

- Crankshaft: The crankshaft is the main shaft that converts the up-and-down motion of the pistons into rotary motion. The crankshaft is connected to the transmission, which transmits the power to the wheels or other machinery.

- Camshaft: The camshaft operates the valves that allow air and fuel into the cylinders and exhaust gases out of the cylinders. The camshaft is typically located above the cylinders and is driven by the crankshaft.

- Valves: The valves control the flow of air and fuel into the cylinders and exhaust gases out of the cylinders. The valves are operated by the camshaft and are typically located in the cylinder head.

Working Principles of a 4-Stroke Engine

The 4-stroke engine operates on the principle of four strokes - intake, compression, power, and exhaust. These strokes are repeated in a cycle to generate power.

- Intake Stroke: In the intake stroke, the piston moves down, creating a vacuum in the cylinder. The intake valve opens, allowing a mixture of air and fuel into the cylinder.

- Compression Stroke: In the compression stroke, the intake valve closes, and the piston moves up, compressing the air-fuel mixture in the cylinder.

- Power Stroke: In the power stroke, the spark plug ignites the compressed air-fuel mixture, causing a small explosion that drives the piston down. The piston is connected to the crankshaft, which converts the up-and-down motion into rotary motion.

- Exhaust Stroke: In the exhaust stroke, the piston moves up again, pushing the exhaust gases out of the cylinder through the exhaust valve.

Benefits of 4-Stroke Technology

The 4-stroke engine has several benefits that have contributed to its widespread adoption. Some of the benefits include:

- Efficiency: 4-stroke engines are more efficient than 2-stroke engines, producing more power while consuming less fuel.

- Reliability: 4-stroke engines are more reliable than 2-stroke engines, with fewer moving parts and a more straightforward design.

- Versatility: 4-stroke engines can be used in a variety of applications, from small generators to large industrial equipment.

Types of 4-Stroke Engines

There are several types of 4-stroke engines, including:

- Gasoline Engines: Gasoline engines use a spark plug to ignite the fuel-air mixture and are commonly used in cars and small generators.

- Diesel Engines: Diesel engines use compression to ignite the fuel-air mixture and are commonly used in trucks and heavy equipment.

- Natural Gas Engines: Natural gas engines use compressed natural gas as a fuel source and are commonly used in industrial applications.

Applications of 4-Stroke Technology

4-stroke engines are used in a variety of applications, including:

- Transportation: 4-stroke engines are used in cars, trucks, and motorcycles.

- Industrial: 4-stroke engines are used in generators, pumps, and other industrial equipment.

- Agriculture: 4-stroke engines are used in tractors and other agricultural equipment.

Gallery of 4-Stroke Engine Applications

Frequently Asked Questions

What is the difference between a 2-stroke and 4-stroke engine?

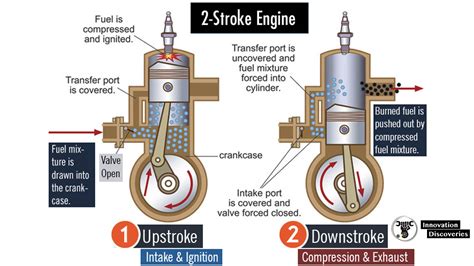

+A 2-stroke engine completes a power cycle in two strokes of the piston, while a 4-stroke engine completes a power cycle in four strokes.

What are the benefits of using a 4-stroke engine?

+4-stroke engines are more efficient, reliable, and versatile than 2-stroke engines.

What are some common applications of 4-stroke engines?

+4-stroke engines are used in transportation, industrial, and agricultural applications.

In conclusion, 4-stroke technology has revolutionized the way we generate power and has become an essential component of modern life. Its efficiency, reliability, and versatility have made it a popular choice for a wide range of applications. As we continue to innovate and improve 4-stroke technology, we can expect to see even more efficient and environmentally friendly engines in the future.