Metal bending is a crucial process in various industries, including aerospace, automotive, and construction. However, traditional metal bending methods can be time-consuming, labor-intensive, and prone to errors. The introduction of Bend-Tech software has revolutionized the metal bending process, offering numerous benefits and improvements. In this article, we will explore five ways Bend-Tech software is transforming the metal bending industry.

What is Bend-Tech Software?

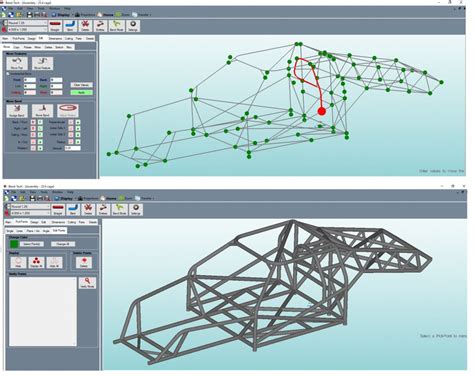

Bend-Tech software is a cutting-edge solution designed to streamline and optimize metal bending processes. This innovative software utilizes advanced algorithms and artificial intelligence to analyze and simulate metal bending operations, enabling fabricators to produce accurate and precise results. By leveraging Bend-Tech software, fabricators can reduce production time, minimize errors, and improve overall efficiency.

1. Improved Accuracy and Precision

One of the primary advantages of Bend-Tech software is its ability to improve accuracy and precision in metal bending operations. By utilizing advanced algorithms and simulations, the software can predict and adjust for various factors that affect the bending process, such as material properties, tooling, and temperature. This results in precise and consistent bends, reducing the need for manual adjustments and rework.

Bend-Tech software also enables fabricators to create complex bends and shapes with ease, allowing for greater design flexibility and creativity. This is particularly beneficial in industries where precise and intricate metalwork is required, such as aerospace and medical device manufacturing.

Benefits of Improved Accuracy and Precision

- Reduced rework and scrap rates

- Increased productivity and efficiency

- Improved product quality and consistency

- Enhanced design flexibility and creativity

2. Streamlined Production and Workflow

Bend-Tech software can significantly streamline production and workflow in metal fabrication shops. By automating many aspects of the bending process, fabricators can reduce manual labor, minimize errors, and improve overall efficiency. The software also enables real-time monitoring and tracking of production, allowing fabricators to identify bottlenecks and optimize their workflow.

Additionally, Bend-Tech software can integrate with existing computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, enabling seamless data transfer and workflow automation. This integration can further reduce production time and improve overall efficiency.

Benefits of Streamlined Production and Workflow

- Reduced production time and lead times

- Improved efficiency and productivity

- Enhanced data transfer and workflow automation

- Real-time monitoring and tracking of production

3. Enhanced Material Utilization and Optimization

Bend-Tech software can help fabricators optimize material utilization and reduce waste. By analyzing and simulating metal bending operations, the software can predict and optimize material usage, reducing scrap rates and improving overall efficiency.

The software can also enable fabricators to create complex shapes and designs while minimizing material waste. This is particularly beneficial in industries where material costs are high, such as aerospace and defense.

Benefits of Enhanced Material Utilization and Optimization

- Reduced material waste and scrap rates

- Improved material utilization and efficiency

- Enhanced design flexibility and creativity

- Reduced material costs and improved profitability

4. Improved Training and Operator Efficiency

Bend-Tech software can also improve training and operator efficiency in metal fabrication shops. By providing real-time feedback and guidance, the software can help operators optimize their bending techniques and improve overall efficiency.

Additionally, the software can enable fabricators to create custom training programs and simulations, allowing operators to practice and improve their skills in a controlled environment. This can reduce training time and improve overall operator efficiency.

Benefits of Improved Training and Operator Efficiency

- Improved operator efficiency and productivity

- Reduced training time and costs

- Enhanced real-time feedback and guidance

- Improved overall shop efficiency and profitability

5. Integration with Emerging Technologies

Finally, Bend-Tech software can integrate with emerging technologies such as Industry 4.0 and the Internet of Things (IoT). By leveraging these technologies, fabricators can create smart factories and shops that are highly efficient, automated, and connected.

The software can also enable fabricators to create digital twins of their metal bending operations, allowing for real-time monitoring and optimization of production. This can further improve overall efficiency and reduce production costs.

Benefits of Integration with Emerging Technologies

- Improved overall efficiency and productivity

- Enhanced real-time monitoring and optimization

- Increased automation and connectivity

- Improved overall shop efficiency and profitability

In conclusion, Bend-Tech software is revolutionizing the metal bending industry by improving accuracy and precision, streamlining production and workflow, enhancing material utilization and optimization, improving training and operator efficiency, and integrating with emerging technologies. By leveraging this innovative software, fabricators can improve overall efficiency, reduce production costs, and enhance product quality and consistency.

We invite you to share your thoughts and experiences with Bend-Tech software in the comments below. How has this software impacted your metal bending operations, and what benefits have you realized?

What is Bend-Tech software?

+Bend-Tech software is a cutting-edge solution designed to streamline and optimize metal bending processes.

How does Bend-Tech software improve accuracy and precision?

+Bend-Tech software utilizes advanced algorithms and simulations to predict and adjust for various factors that affect the bending process, resulting in precise and consistent bends.

Can Bend-Tech software integrate with emerging technologies?

+Yes, Bend-Tech software can integrate with emerging technologies such as Industry 4.0 and the Internet of Things (IoT).