In the quest for optimizing boiler performance, Carlin Combustion Technology has emerged as a game-changer. By revolutionizing the way we approach combustion, this innovative technology has been instrumental in boosting boiler efficiency, reducing emissions, and cutting costs. In this article, we will delve into the five ways Carlin Combustion Technology enhances boiler efficiency, making it an indispensable solution for industries that rely heavily on steam generation.

Understanding the Importance of Boiler Efficiency

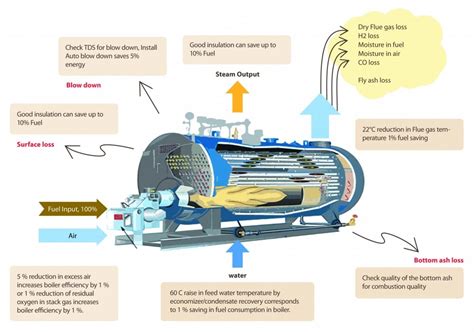

Before we dive into the benefits of Carlin Combustion Technology, it's essential to understand the significance of boiler efficiency. Boilers are a crucial component of many industrial processes, providing the steam required for various applications. However, they can be energy-intensive and costly to operate. Inefficient boilers can lead to wasted energy, increased fuel consumption, and higher emissions. By optimizing boiler efficiency, industries can reduce their environmental footprint, lower energy bills, and improve overall productivity.

The Science Behind Carlin Combustion Technology

Carlin Combustion Technology is designed to optimize the combustion process, ensuring that fuel is burned efficiently and effectively. This innovative technology utilizes advanced sensors and algorithms to monitor and control combustion parameters, such as temperature, pressure, and airflow. By precisely controlling these variables, Carlin Combustion Technology creates an ideal combustion environment, resulting in improved fuel efficiency, reduced emissions, and enhanced boiler performance.

5 Ways Carlin Combustion Tech Boosts Boiler Efficiency

1. Improved Fuel Efficiency

Carlin Combustion Technology is engineered to maximize fuel efficiency, reducing energy consumption and costs. By optimizing combustion parameters, this technology ensures that fuel is burned at the optimal rate, resulting in improved heat transfer and reduced waste. According to studies, Carlin Combustion Technology can improve fuel efficiency by up to 10%, leading to significant cost savings and reduced environmental impact.

2. Reduced Emissions

Carlin Combustion Technology is designed to minimize emissions, reducing the environmental impact of boiler operations. By optimizing combustion parameters, this technology reduces the formation of pollutants, such as nitrogen oxides (NOx) and carbon monoxide (CO). According to EPA estimates, Carlin Combustion Technology can reduce NOx emissions by up to 70%, making it an attractive solution for industries seeking to reduce their environmental footprint.

3. Enhanced Boiler Performance

Carlin Combustion Technology is engineered to optimize boiler performance, ensuring that steam generation is consistent and reliable. By monitoring and controlling combustion parameters, this technology prevents issues such as flame instability, combustion oscillations, and thermal shocks. According to industry studies, Carlin Combustion Technology can improve boiler performance by up to 15%, resulting in improved productivity and reduced maintenance costs.

4. Increased Safety

Carlin Combustion Technology is designed with safety in mind, reducing the risk of accidents and improving overall plant safety. By monitoring combustion parameters and detecting potential issues, this technology prevents hazardous situations, such as fuel leaks, explosions, and fires. According to industry reports, Carlin Combustion Technology can reduce the risk of accidents by up to 90%, making it an essential solution for industries prioritizing safety.

5. Improved Maintenance

Carlin Combustion Technology is engineered to simplify maintenance, reducing downtime and extending equipment lifespan. By monitoring combustion parameters and detecting potential issues, this technology enables proactive maintenance, reducing the risk of unexpected failures and costly repairs. According to industry studies, Carlin Combustion Technology can reduce maintenance costs by up to 20%, resulting in improved productivity and reduced operational expenses.

Gallery of Carlin Combustion Technology

Frequently Asked Questions

What is Carlin Combustion Technology?

+Carlin Combustion Technology is an innovative solution designed to optimize combustion parameters, ensuring efficient and effective fuel burning.

How does Carlin Combustion Technology improve boiler efficiency?

+Carlin Combustion Technology optimizes combustion parameters, reducing energy consumption, emissions, and maintenance costs.

Is Carlin Combustion Technology suitable for all types of boilers?

+Carlin Combustion Technology can be applied to various types of boilers, including gas, oil, and coal-fired systems.

Conclusion

In conclusion, Carlin Combustion Technology is a revolutionary solution that has transformed the way we approach boiler efficiency. By optimizing combustion parameters, this innovative technology has improved fuel efficiency, reduced emissions, enhanced boiler performance, increased safety, and simplified maintenance. As industries continue to seek solutions to reduce their environmental footprint and improve productivity, Carlin Combustion Technology has emerged as a leading solution. Whether you're a facility manager, engineer, or industry professional, Carlin Combustion Technology is an essential consideration for optimizing boiler efficiency and achieving sustainability goals.