Precision engineering is a field that requires meticulous attention to detail and a high level of accuracy. The use of diamond machining technology has revolutionized the industry, enabling the creation of complex components with unprecedented precision. In this article, we will explore five ways diamond machining tech enhances precision engineering.

The Importance of Precision Engineering

Precision engineering is a critical component of various industries, including aerospace, automotive, and medical devices. The field involves the design, development, and manufacture of complex components that require extremely high levels of accuracy. Precision engineering enables the creation of components that are not only functional but also aesthetically pleasing.

The Role of Diamond Machining Technology

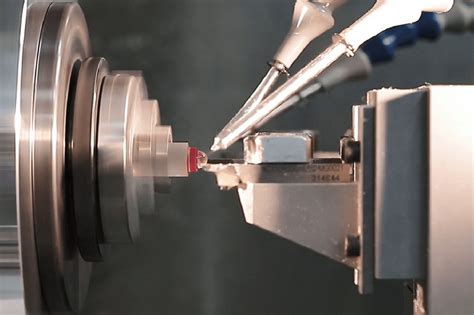

Diamond machining technology is a game-changer in the field of precision engineering. This technology uses diamond-coated cutting tools to machine complex components with unparalleled precision. The use of diamond machining technology offers several benefits, including improved accuracy, increased productivity, and reduced costs.

5 Ways Diamond Machining Tech Enhances Precision Engineering

1. Improved Accuracy

Diamond machining technology enables the creation of complex components with extremely high levels of accuracy. The use of diamond-coated cutting tools allows for precise control over the machining process, resulting in components that meet exacting specifications.

2. Increased Productivity

Diamond machining technology enables precision engineers to increase productivity while maintaining high levels of accuracy. The use of diamond-coated cutting tools allows for faster machining times, resulting in increased efficiency and reduced costs.

3. Reduced Costs

Diamond machining technology enables precision engineers to reduce costs while maintaining high levels of accuracy. The use of diamond-coated cutting tools allows for extended tool life, resulting in reduced maintenance and replacement costs.

4. Enhanced Surface Finish

Diamond machining technology enables precision engineers to create complex components with enhanced surface finishes. The use of diamond-coated cutting tools allows for precise control over the machining process, resulting in components with improved surface finishes.

5. Increased Design Flexibility

Diamond machining technology enables precision engineers to create complex components with increased design flexibility. The use of diamond-coated cutting tools allows for precise control over the machining process, resulting in components that meet exacting specifications.

Gallery of Diamond Machining Tech

Frequently Asked Questions

What is diamond machining technology?

+Diamond machining technology is a machining process that uses diamond-coated cutting tools to machine complex components with unprecedented precision.

What are the benefits of diamond machining technology?

+The benefits of diamond machining technology include improved accuracy, increased productivity, reduced costs, enhanced surface finish, and increased design flexibility.

What industries use diamond machining technology?

+Diamond machining technology is used in various industries, including aerospace, automotive, and medical devices.

Final Thoughts

Diamond machining technology has revolutionized the field of precision engineering, enabling the creation of complex components with unprecedented precision. The use of diamond-coated cutting tools offers several benefits, including improved accuracy, increased productivity, reduced costs, enhanced surface finish, and increased design flexibility. As the demand for precision engineering components continues to grow, diamond machining technology is poised to play an increasingly important role in the industry.