In today's high-tech world, wiring diagrams play a vital role in ensuring the efficient and safe operation of various systems, including those found in vehicles. A wiring diagram is a visual representation of the electrical connections and circuits in a system, serving as a blueprint for technicians, engineers, and DIY enthusiasts alike. In the context of Fuel Tech, a leading brand in engine management systems, wiring diagrams are essential for proper installation, troubleshooting, and maintenance. Here are six essential Fuel Tech wiring diagram tips to help you navigate the complex world of engine management wiring.

Understanding the Basics of Fuel Tech Wiring Diagrams

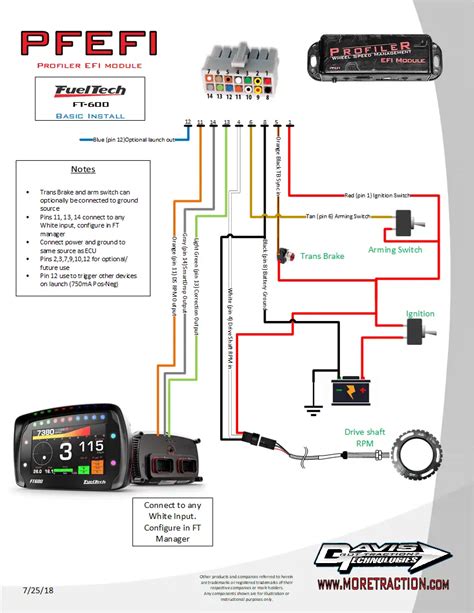

Before diving into the tips, it's crucial to understand the basics of Fuel Tech wiring diagrams. These diagrams typically consist of a series of symbols, lines, and annotations that represent the various components and connections within the engine management system. Familiarizing yourself with the standard symbols and notations used in Fuel Tech wiring diagrams will make it easier to read and interpret the diagrams.

Tip 1: Identify the Correct Wiring Diagram for Your Vehicle

With numerous vehicle models and engine configurations available, it's essential to identify the correct wiring diagram for your specific vehicle. Fuel Tech provides wiring diagrams for various vehicle models and engine types, so make sure to select the correct diagram for your application. This will ensure that you're working with the correct wiring layout and avoid any potential errors or safety hazards.

Reading and Interpreting Fuel Tech Wiring Diagrams

Reading and interpreting Fuel Tech wiring diagrams requires attention to detail and a basic understanding of electrical circuits. Here are some key elements to look for when reading a Fuel Tech wiring diagram:

- Component symbols: These represent the various components within the engine management system, such as sensors, actuators, and control modules.

- Wire colors and labels: These indicate the color and function of each wire, making it easier to identify and connect the correct wires.

- Connection points: These represent the points where wires connect to components or other wires.

Tip 2: Use the Correct Tools and Materials

When working with Fuel Tech wiring diagrams, it's essential to use the correct tools and materials to ensure accurate and safe connections. This includes:

- A wiring diagram specific to your vehicle model and engine configuration

- A multimeter or wiring tester to verify connections and voltages

- High-quality wire and connectors to ensure reliable connections

- A soldering iron and solder to make secure connections

Troubleshooting with Fuel Tech Wiring Diagrams

Fuel Tech wiring diagrams are also an invaluable resource for troubleshooting engine management system issues. By analyzing the wiring diagram, you can identify potential problems and make necessary repairs. Here are some troubleshooting tips:

- Consult the wiring diagram to identify the affected circuit or component

- Use a multimeter or wiring tester to verify connections and voltages

- Check for any signs of damage, wear, or corrosion on wires and connectors

Tip 3: Label and Organize Wires and Connectors

Properly labeling and organizing wires and connectors is crucial for maintaining a clean and efficient engine management system. Use the wiring diagram to identify the correct wire colors and labels, and make sure to label each wire and connector accordingly. This will make it easier to identify and connect wires during installation or troubleshooting.

Modifying Fuel Tech Wiring Diagrams

In some cases, you may need to modify the Fuel Tech wiring diagram to accommodate custom engine modifications or upgrades. Here are some tips for modifying Fuel Tech wiring diagrams:

- Consult the original wiring diagram to understand the existing circuit layout

- Use a wiring diagram software or app to create a modified diagram

- Verify the modified diagram with a qualified technician or engineer to ensure accuracy and safety

Tip 4: Keep a Record of Modifications and Repairs

Keeping a record of modifications and repairs is essential for maintaining a well-documented engine management system. Use a notebook or digital tool to record any changes or repairs made to the wiring diagram, including:

- Dates and descriptions of modifications and repairs

- Before-and-after photos of wiring connections and components

- Notes on any troubleshooting or diagnostic procedures used

Conclusion and Next Steps

In conclusion, Fuel Tech wiring diagrams are a critical resource for anyone working with engine management systems. By following the six essential tips outlined in this article, you'll be better equipped to read, interpret, and modify Fuel Tech wiring diagrams with confidence. Remember to always consult the original wiring diagram, use the correct tools and materials, and keep a record of modifications and repairs.

Whether you're a seasoned technician or a DIY enthusiast, Fuel Tech wiring diagrams are an invaluable resource for ensuring the safe and efficient operation of your engine management system. By mastering the art of reading and interpreting Fuel Tech wiring diagrams, you'll be able to tackle even the most complex engine management system challenges with ease.

Gallery of Fuel Tech Wiring Diagrams

Frequently Asked Questions

What is a Fuel Tech wiring diagram?

+A Fuel Tech wiring diagram is a visual representation of the electrical connections and circuits in a Fuel Tech engine management system.

Why is it important to use the correct wiring diagram for my vehicle?

+Using the correct wiring diagram ensures that you're working with the correct wiring layout and avoids potential errors or safety hazards.

Can I modify a Fuel Tech wiring diagram to accommodate custom engine modifications?

+Yes, but it's essential to consult the original wiring diagram and verify the modified diagram with a qualified technician or engineer to ensure accuracy and safety.