Working in the field of lubrication technology can be a rewarding and challenging career path. As a Lube Tech, you will play a crucial role in maintaining the efficiency and effectiveness of machinery and equipment in various industries. In this article, we will delve into the key responsibilities of a Lube Tech job description, highlighting the essential duties and skills required for success in this field.

What is a Lube Tech?

A Lube Tech, also known as a lubrication technician, is a professional responsible for the installation, maintenance, and repair of lubrication systems in industrial settings. Their primary goal is to ensure that machinery and equipment are properly lubricated to prevent wear and tear, reduce downtime, and optimize performance.

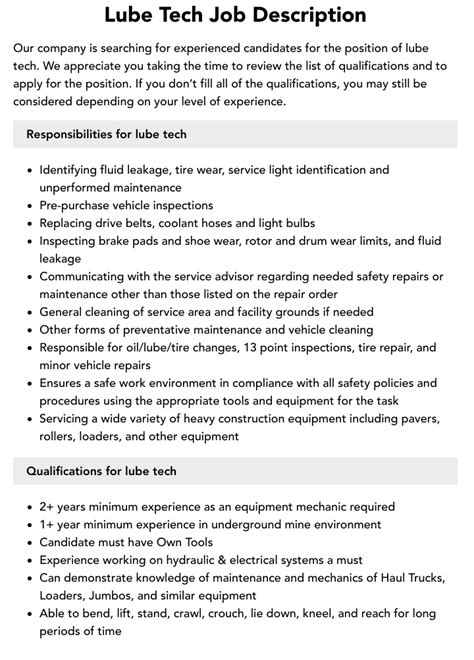

7 Key Responsibilities of a Lube Tech Job Description

As a Lube Tech, your daily tasks will involve a range of activities that require technical expertise, attention to detail, and strong problem-solving skills. Here are the 7 key responsibilities of a Lube Tech job description:

1. Lubrication System Installation and Maintenance

As a Lube Tech, you will be responsible for installing and maintaining lubrication systems, including pumps, filters, and piping. This involves ensuring that all components are properly connected and functioning as intended.

Key Skills:

- Ability to read and interpret technical drawings and schematics

- Knowledge of lubrication system components and their functions

- Strong mechanical aptitude and troubleshooting skills

2. Lubricant Selection and Application

Lube Techs must select the appropriate lubricants for various applications, taking into account factors such as temperature, pressure, and equipment type. They must also ensure that lubricants are applied correctly to prevent contamination and waste.

Key Skills:

- Knowledge of lubricant properties and applications

- Ability to analyze equipment specifications and operating conditions

- Strong attention to detail and adherence to safety protocols

3. Troubleshooting and Repair

Lube Techs must be able to diagnose and repair issues with lubrication systems, including leaks, clogs, and equipment malfunctions. This requires strong problem-solving skills and the ability to work independently.

Key Skills:

- Strong mechanical aptitude and troubleshooting skills

- Ability to analyze data and identify root causes of problems

- Effective communication and collaboration with maintenance teams

4. Predictive Maintenance and Condition Monitoring

Lube Techs use predictive maintenance techniques, such as vibration analysis and oil sampling, to monitor equipment condition and predict potential failures. This enables proactive maintenance and reduces downtime.

Key Skills:

- Knowledge of predictive maintenance techniques and tools

- Ability to analyze data and identify trends

- Strong understanding of equipment reliability and maintenance principles

5. Safety and Compliance

Lube Techs must ensure that all work is performed in a safe and compliant manner, adhering to industry regulations and company policies. This includes proper handling of hazardous materials and waste disposal.

Key Skills:

- Knowledge of safety protocols and regulations

- Ability to identify and mitigate potential hazards

- Strong commitment to safety and environmental responsibility

6. Documentation and Reporting

Lube Techs must maintain accurate records of maintenance activities, including lubricant usage, equipment condition, and repair history. This information is used to optimize maintenance schedules and improve equipment reliability.

Key Skills:

- Ability to maintain accurate and detailed records

- Strong organizational and time management skills

- Effective communication and reporting skills

7. Training and Development

Lube Techs must stay up-to-date with the latest technologies and techniques in lubrication and maintenance. This includes participating in training programs, attending industry conferences, and seeking certification.

Key Skills:

- Commitment to ongoing learning and professional development

- Ability to adapt to new technologies and procedures

- Strong analytical and problem-solving skills

Gallery of Lube Tech Images

Frequently Asked Questions

What is the typical salary range for a Lube Tech?

+The typical salary range for a Lube Tech varies depending on location, industry, and level of experience. However, according to national averages, a Lube Tech can expect to earn between $45,000 and $70,000 per year.

What kind of education and training is required to become a Lube Tech?

+To become a Lube Tech, you typically need a high school diploma or equivalent, as well as completion of a vocational training program in lubrication technology or a related field. Many Lube Techs also obtain certifications, such as the Certified Lubrication Technician (CLT) designation.

What are the most common industries that employ Lube Techs?

+Lube Techs are employed in a variety of industries, including manufacturing, mining, construction, and transportation. They may also work in power generation, oil and gas, and other industries that rely heavily on machinery and equipment.

In conclusion, the role of a Lube Tech is a critical one, requiring a unique blend of technical expertise, problem-solving skills, and attention to detail. By understanding the key responsibilities of a Lube Tech job description, you can better appreciate the importance of this profession and the value it brings to industries around the world.