In the world of manufacturing, efficiency is key to staying competitive. One area where manufacturers can gain a significant edge is by adopting new technologies in roll forming. Roll forming is a process that involves bending and shaping metal into desired shapes and profiles. With the advent of new technologies, roll formers have become more sophisticated, enabling manufacturers to produce high-quality products faster and more efficiently. In this article, we will explore 7 ways new tech roll formers boost manufacturing efficiency.

What are Roll Formers?

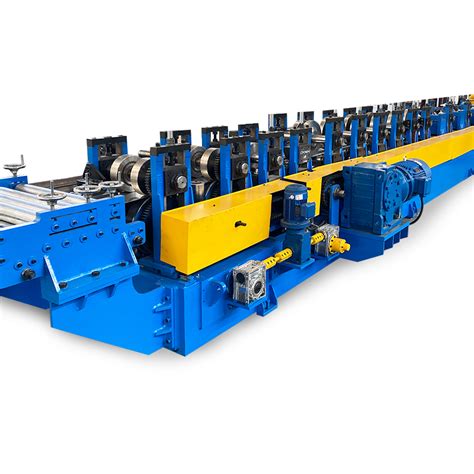

Before we dive into the benefits of new tech roll formers, let's take a brief look at what roll formers are and how they work. Roll formers are machines that shape metal into desired profiles using a series of rollers. The metal is fed through the rollers, which bend and shape it into the desired shape. Roll formers are commonly used in various industries, including construction, automotive, and aerospace.

1. Increased Speed and Productivity

New tech roll formers are designed to work faster and more efficiently than their traditional counterparts. With advanced drives and control systems, these machines can produce high-quality products at speeds of up to 100 meters per minute. This increased speed and productivity enable manufacturers to meet tight deadlines and increase their overall output.

2. Improved Accuracy and Precision

New tech roll formers are equipped with advanced sensors and control systems that ensure accurate and precise production. These machines can detect even the slightest deviations in the metal and adjust their rollers accordingly. This ensures that the final product meets the required specifications and quality standards.

3. Reduced Material Waste

One of the significant advantages of new tech roll formers is their ability to minimize material waste. These machines are designed to optimize material usage, reducing the amount of scrap metal generated during the production process. This not only saves manufacturers money but also reduces their environmental footprint.

4. Enhanced Flexibility and Versatility

New tech roll formers are designed to be highly flexible and versatile. These machines can produce a wide range of profiles and shapes, from simple to complex, using various types of metal. This enables manufacturers to produce a diverse range of products on a single machine, reducing the need for multiple machines and increasing overall efficiency.

5. Improved Operator Safety

New tech roll formers are designed with operator safety in mind. These machines are equipped with advanced safety features, such as automatic shut-off and emergency stops, which minimize the risk of accidents and injuries. Additionally, these machines are designed to reduce noise levels and vibrations, creating a more comfortable working environment for operators.

6. Reduced Maintenance and Downtime

New tech roll formers are designed to require minimal maintenance and downtime. These machines are equipped with advanced diagnostic systems that detect potential issues before they occur, reducing the need for costly repairs and downtime. Additionally, these machines are designed to be easily serviced and maintained, reducing the time and cost associated with maintenance.

7. Increased Energy Efficiency

Finally, new tech roll formers are designed to be energy efficient. These machines use advanced drives and control systems that optimize energy consumption, reducing the amount of energy required to produce high-quality products. This not only saves manufacturers money on energy costs but also reduces their environmental footprint.

Conclusion

In conclusion, new tech roll formers offer a range of benefits that can boost manufacturing efficiency. From increased speed and productivity to improved accuracy and precision, these machines are designed to help manufacturers produce high-quality products faster and more efficiently. With their ability to reduce material waste, enhance flexibility and versatility, improve operator safety, reduce maintenance and downtime, and increase energy efficiency, new tech roll formers are an essential investment for any manufacturer looking to stay competitive in today's fast-paced manufacturing landscape.

Gallery of Roll Formers in Action

FAQs

What are roll formers used for?

+Roll formers are used to shape metal into desired profiles and shapes. They are commonly used in various industries, including construction, automotive, and aerospace.

How do new tech roll formers improve manufacturing efficiency?

+New tech roll formers improve manufacturing efficiency by increasing speed and productivity, improving accuracy and precision, reducing material waste, enhancing flexibility and versatility, improving operator safety, reducing maintenance and downtime, and increasing energy efficiency.

What are the benefits of using new tech roll formers?

+The benefits of using new tech roll formers include increased productivity, improved accuracy and precision, reduced material waste, enhanced flexibility and versatility, improved operator safety, reduced maintenance and downtime, and increased energy efficiency.