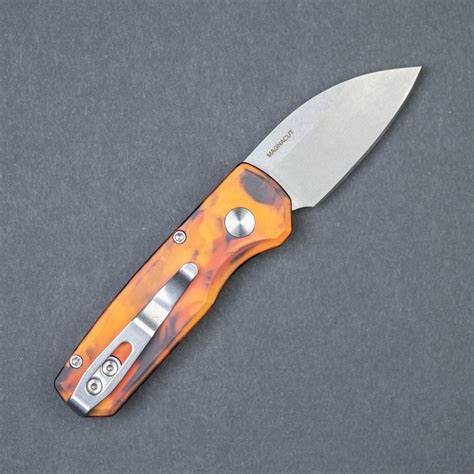

When it comes to machining and manufacturing, precision and efficiency are key. The Pro-Tech Runt 5 Magnacut is a state-of-the-art machine designed to deliver exceptional performance and versatility. In this article, we'll dive into the top 5 features of this impressive machine, exploring its capabilities, benefits, and what sets it apart from the competition.

Precision and Versatility

The Pro-Tech Runt 5 Magnacut is built for precision and versatility. Its robust design and advanced technology enable it to tackle a wide range of tasks, from simple cuts to complex machining operations. With its impressive specifications, this machine is perfect for various industries, including aerospace, automotive, and medical.

High-Speed Machining Capabilities

One of the standout features of the Pro-Tech Runt 5 Magnacut is its high-speed machining capabilities. With a spindle speed of up to 24,000 rpm, this machine can achieve incredible cutting speeds, making it ideal for high-volume production runs. Its advanced coolant system and precision spindle ensure smooth operation, even at the highest speeds.

Advanced Control System

The Pro-Tech Runt 5 Magnacut features an advanced control system that provides unparalleled precision and control. Its intuitive interface and customizable settings enable operators to optimize their machining processes, achieving the highest level of accuracy and quality.

Reliability and Durability

The Pro-Tech Runt 5 Magnacut is built to last, with a robust design and high-quality components that ensure reliability and durability. Its advanced cooling system and precision engineering minimize wear and tear, reducing downtime and maintenance costs.

Enhanced Operator Safety

The Pro-Tech Runt 5 Magnacut prioritizes operator safety with its advanced safety features. Its secure enclosure and emergency stop system ensure a safe working environment, protecting operators from potential hazards.

Why Choose the Pro-Tech Runt 5 Magnacut?

The Pro-Tech Runt 5 Magnacut is an exceptional machine that offers unparalleled precision, versatility, and performance. Its advanced features and robust design make it an ideal choice for a wide range of industries and applications.

Increased Productivity

The Pro-Tech Runt 5 Magnacut's high-speed machining capabilities and advanced control system enable operators to achieve higher productivity rates, reducing production time and increasing efficiency.

Improved Accuracy

The machine's precision engineering and advanced control system ensure exceptional accuracy, reducing errors and improving overall product quality.

Enhanced Safety

The Pro-Tech Runt 5 Magnacut prioritizes operator safety with its advanced safety features, protecting operators from potential hazards and ensuring a safe working environment.

Reduced Maintenance

The machine's robust design and high-quality components minimize wear and tear, reducing downtime and maintenance costs.

What is the maximum spindle speed of the Pro-Tech Runt 5 Magnacut?

+The maximum spindle speed of the Pro-Tech Runt 5 Magnacut is 24,000 rpm.

What is the primary material used in the construction of the Pro-Tech Runt 5 Magnacut?

+The primary material used in the construction of the Pro-Tech Runt 5 Magnacut is high-quality steel.

What is the typical power consumption of the Pro-Tech Runt 5 Magnacut?

+The typical power consumption of the Pro-Tech Runt 5 Magnacut is 20 kW.

We hope this article has provided you with valuable insights into the Pro-Tech Runt 5 Magnacut's impressive features and capabilities. Whether you're a seasoned machinist or just starting out, this machine is sure to deliver exceptional results and take your production to the next level.