The world of process technology is an exciting and rapidly evolving field that plays a crucial role in various industries, including manufacturing, engineering, and quality control. Process technicians are highly skilled professionals who oversee the production process, ensuring that it runs smoothly, efficiently, and safely. In this article, we will delve into the world of process technology, exploring the job description, responsibilities, and requirements of a process technician.

What is a Process Technician?

A process technician is a skilled professional responsible for operating, maintaining, and troubleshooting equipment and systems used in various industries, such as chemical processing, oil and gas, power generation, and pharmaceuticals. They work closely with engineers, operators, and other technicians to ensure that the production process is optimized, efficient, and compliant with safety and quality standards.

Job Description:

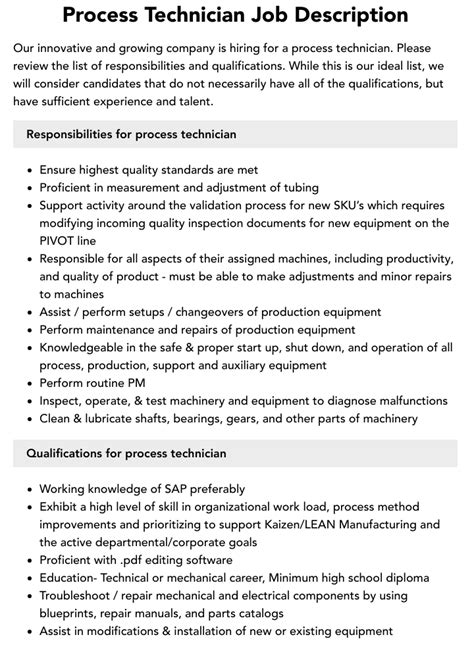

The primary responsibility of a process technician is to monitor and control the production process, ensuring that it runs smoothly and efficiently. This involves:

- Operating and maintaining equipment, such as pumps, valves, and control systems

- Monitoring process parameters, such as temperature, pressure, and flow rates

- Troubleshooting equipment malfunctions and taking corrective action

- Performing routine maintenance tasks, such as cleaning and replacing parts

- Collaborating with engineers and other technicians to optimize process performance

- Ensuring compliance with safety and quality standards, such as OSHA regulations and ISO 9001

Responsibilities:

The responsibilities of a process technician can vary depending on the industry and specific job requirements. However, some common responsibilities include:

- Equipment Operation and Maintenance: Process technicians are responsible for operating and maintaining equipment, such as pumps, valves, and control systems. This involves performing routine maintenance tasks, such as cleaning and replacing parts, and troubleshooting equipment malfunctions.

- Process Monitoring and Control: Process technicians monitor process parameters, such as temperature, pressure, and flow rates, to ensure that the production process is running smoothly and efficiently.

- Troubleshooting: Process technicians troubleshoot equipment malfunctions and take corrective action to resolve issues quickly and efficiently.

- Collaboration: Process technicians work closely with engineers, operators, and other technicians to optimize process performance and ensure compliance with safety and quality standards.

- Safety and Quality: Process technicians ensure compliance with safety and quality standards, such as OSHA regulations and ISO 9001.

Requirements:

To become a process technician, you typically need to meet the following requirements:

- Education: A high school diploma or equivalent is typically required, although some employers may prefer or require a post-secondary certificate or degree in a related field, such as process technology or engineering.

- Training: Many process technicians complete an apprenticeship program or receive on-the-job training to learn the skills and knowledge required for the job.

- Certification: Some employers may require process technicians to be certified in a specific area, such as instrumentation or control systems.

- Skills: Process technicians need to have strong technical skills, including knowledge of process control systems, instrumentation, and electrical systems. They also need to have good problem-solving and communication skills.

Work Environment:

Process technicians typically work in industrial settings, such as manufacturing plants, oil refineries, or power generation facilities. They may work in a variety of environments, including:

- Control Rooms: Process technicians may work in control rooms, monitoring process parameters and controlling equipment.

- Field Settings: Process technicians may work in field settings, such as on the plant floor or in the field, where they may be exposed to hazardous materials or extreme temperatures.

- Office Settings: Process technicians may also work in office settings, where they may be responsible for data analysis, reporting, and other administrative tasks.

Career Advancement:

Process technicians can advance their careers by taking on additional responsibilities, such as:

- Senior Technician: Senior technicians may be responsible for leading a team of technicians, troubleshooting complex equipment malfunctions, and optimizing process performance.

- Engineering Roles: Process technicians may move into engineering roles, such as design engineer or process engineer, where they may be responsible for designing and developing new processes and equipment.

- Management Roles: Process technicians may move into management roles, such as production manager or operations manager, where they may be responsible for overseeing the production process and ensuring compliance with safety and quality standards.

Conclusion:

In conclusion, process technicians play a critical role in various industries, ensuring that the production process runs smoothly, efficiently, and safely. To become a process technician, you typically need to meet specific requirements, including education, training, and certification. Process technicians can advance their careers by taking on additional responsibilities, such as senior technician, engineering roles, or management roles.

Gallery of Process Technician:

FAQs:

What is a process technician?

+A process technician is a skilled professional responsible for operating, maintaining, and troubleshooting equipment and systems used in various industries.

What are the responsibilities of a process technician?

+Process technicians are responsible for operating and maintaining equipment, monitoring process parameters, troubleshooting equipment malfunctions, and ensuring compliance with safety and quality standards.

What are the requirements to become a process technician?

+To become a process technician, you typically need to meet specific requirements, including education, training, and certification.