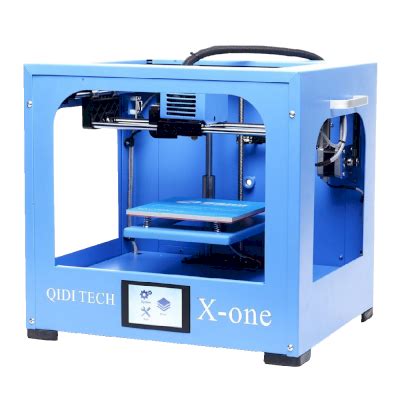

The world of 3D printing has revolutionized the way we design, create, and innovate. With the Qidi Tech X One2, a highly-regarded and versatile 3D printer, users can bring their ideas to life with precision and accuracy. However, mastering this machine requires more than just a basic understanding of its functions. In this article, we'll delve into five essential tips to help you unlock the full potential of your Qidi Tech X One2 and elevate your 3D printing skills.

Tip 1: Calibrate Your Printer for Optimal Performance

Proper calibration is the foundation of successful 3D printing. The Qidi Tech X One2 comes with an auto-calibration feature, but it's essential to double-check and fine-tune the settings to ensure the best results.

To calibrate your printer, follow these steps:

- Level the print bed using the auto-leveling feature or manually adjust the screws.

- Adjust the Z-axis offset to ensure the correct distance between the nozzle and the print bed.

- Check the belt tension and adjust if necessary to prevent sagging or too much tension.

- Run a calibration print to verify the accuracy of your adjustments.

By taking the time to calibrate your Qidi Tech X One2, you'll be able to achieve precise prints with minimal warping or distortion.

Tip 2: Choose the Right Filament for Your Project

With the vast array of filaments available, selecting the right one for your project can be overwhelming. The Qidi Tech X One2 supports a wide range of filaments, including PLA, ABS, PETG, and more.

When choosing a filament, consider the following factors:

- Material properties: Different filaments have unique characteristics, such as strength, flexibility, and thermal resistance.

- Print settings: Some filaments require specific temperature, speed, or layer height settings.

- Project requirements: Consider the intended use of your print, such as durability, appearance, or functionality.

By selecting the right filament for your project, you'll be able to achieve the desired results and ensure a successful print.

Troubleshooting Common Filament Issues

- Clogged nozzle: Use a nozzle cleaning tool or replace the nozzle if necessary.

- Warping or curling: Adjust the print bed temperature, use a brim or raft, or increase the infill density.

- Stringing or oozing: Adjust the retraction settings, increase the travel speed, or decrease the nozzle temperature.

Tip 3: Optimize Your Print Settings for Quality and Speed

The Qidi Tech X One2 offers a wide range of print settings to customize your printing experience. However, finding the perfect balance between quality and speed can be challenging.

To optimize your print settings, consider the following:

- Layer height: A lower layer height will result in a more detailed print, but may increase print time.

- Infill density: A higher infill density will increase the strength and weight of the print, but may also increase print time.

- Print speed: A faster print speed may sacrifice some quality, but can significantly reduce print time.

- Temperature: Adjusting the nozzle and print bed temperatures can affect the print quality, speed, and filament flow.

By experimenting with different print settings, you'll be able to find the perfect balance between quality and speed for your specific project.

Best Practices for Print Setting Optimization

- Start with a standard print setting profile and adjust as needed.

- Use the Qidi Tech X One2's built-in print setting presets as a starting point.

- Experiment with small changes to print settings to avoid drastic changes.

- Keep a record of your print settings and results to refine your approach.

Tip 4: Post-Processing Techniques for a Professional Finish

While the Qidi Tech X One2 produces high-quality prints, post-processing techniques can elevate your prints to a professional level.

Some common post-processing techniques include:

- Sanding: Use progressively finer grit sandpaper to smooth out the print surface.

- Painting: Apply a coat of primer and paint to achieve a uniform color and finish.

- Assembly: Use glue, screws, or other fasteners to assemble multiple prints into a single unit.

By applying these post-processing techniques, you'll be able to achieve a professional finish and take your prints to the next level.

Common Post-Processing Mistakes to Avoid

- Insufficient sanding: Failing to sand the print surface can result in a rough finish.

- Inadequate primer: Not applying a primer can cause paint to flake or peel off.

- Over-tightening: Applying too much pressure during assembly can damage the print or cause it to break.

Tip 5: Maintenance and Upgrades for Long-Term Performance

Regular maintenance and upgrades are crucial for extending the lifespan of your Qidi Tech X One2 and ensuring optimal performance.

Some essential maintenance tasks include:

- Cleaning the print bed and nozzle: Regularly clean the print bed and nozzle to prevent debris buildup.

- Lubricating moving parts: Apply lubricant to moving parts, such as the Z-axis and X-axis rods.

- Updating firmware: Regularly update the firmware to ensure you have the latest features and bug fixes.

By performing regular maintenance and upgrades, you'll be able to ensure your Qidi Tech X One2 continues to perform optimally and produce high-quality prints.

Upgrades for Enhanced Performance

- Upgrading the print bed: Consider upgrading to a heated chamber or a borosilicate glass print bed for improved adhesion and thermal stability.

- Installing a new nozzle: Upgrade to a high-temperature nozzle or a nozzle with a different diameter to improve print quality and speed.

- Adding a filament sensor: Install a filament sensor to detect filament runout and prevent print failures.

By following these five tips, you'll be well on your way to mastering your Qidi Tech X One2 and unlocking its full potential. Remember to always follow safety guidelines, use high-quality materials, and experiment with different techniques to achieve the best results.

What is the recommended print bed temperature for the Qidi Tech X One2?

+The recommended print bed temperature for the Qidi Tech X One2 varies depending on the filament used. For PLA, a temperature range of 50-60°C is recommended, while for ABS, a temperature range of 90-100°C is recommended.

How do I calibrate the Z-axis on the Qidi Tech X One2?

+To calibrate the Z-axis on the Qidi Tech X One2, follow these steps: 1) Level the print bed, 2) Adjust the Z-axis offset, 3) Run a calibration print to verify the accuracy of your adjustments.

What is the maximum print resolution of the Qidi Tech X One2?

+The maximum print resolution of the Qidi Tech X One2 is 100 microns.