Space exploration has always been a realm of human fascination, and with advancements in technology, the possibilities seem endless. At the forefront of this revolution is the development of printable technologies, specifically printable rover tech. In this article, we will delve into the world of printable rover tech, its benefits, working mechanisms, and potential applications in space exploration.

What is Printable Rover Tech?

Printable rover tech refers to the use of 3D printing and other additive manufacturing techniques to create rover components, such as chassis, wheels, and even entire vehicles. This technology has the potential to revolutionize the way we design, build, and deploy rovers for space exploration.

Benefits of Printable Rover Tech

Printable rover tech offers several benefits over traditional manufacturing methods. Some of the most significant advantages include:

- Reduced weight: 3D printing allows for the creation of complex geometries and structures that can be significantly lighter than their traditionally manufactured counterparts. This is particularly important in space exploration, where every gram of weight can impact fuel efficiency and mission duration.

- Increased customization: With 3D printing, rover components can be tailored to specific mission requirements, allowing for greater flexibility and adaptability.

- Faster production: 3D printing can produce complex components at a fraction of the time required by traditional manufacturing methods, enabling rapid prototyping and deployment.

- Cost-effectiveness: 3D printing can reduce material waste and energy consumption, making it a more cost-effective option for producing rover components.

Working Mechanisms of Printable Rover Tech

Printable rover tech relies on advanced 3D printing technologies, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). These technologies enable the creation of complex components with high precision and accuracy.

- FDM: FDM uses melted plastic to create components layer by layer. This technology is ideal for producing large, complex components, such as rover chassis.

- SLA: SLA uses a laser to solidify liquid resin, creating highly detailed and accurate components. This technology is ideal for producing small, intricate components, such as rover electronics.

- SLS: SLS uses a laser to fuse together particles of a powdered material, creating highly durable and precise components. This technology is ideal for producing load-bearing components, such as rover wheels.

Applications of Printable Rover Tech

Printable rover tech has numerous applications in space exploration, including:

- Mars exploration: Printable rover tech can be used to create rovers that can navigate the Martian terrain, collect samples, and conduct experiments.

- Lunar exploration: Printable rover tech can be used to create rovers that can explore the lunar surface, collect samples, and conduct experiments.

- Asteroid exploration: Printable rover tech can be used to create rovers that can explore asteroids, collect samples, and conduct experiments.

Steps to Implement Printable Rover Tech

Implementing printable rover tech requires several steps, including:

- Design: Design the rover components using computer-aided design (CAD) software.

- Printing: Print the rover components using 3D printing technologies, such as FDM, SLA, or SLS.

- Assembly: Assemble the rover components into a functional vehicle.

- Testing: Test the rover to ensure its functionality and performance.

Challenges and Limitations

While printable rover tech offers numerous benefits, it also faces several challenges and limitations, including:

- Material limitations: 3D printing materials may not have the same strength and durability as traditionally manufactured materials.

- Scalability: 3D printing can be a time-consuming process, making it challenging to produce large quantities of rover components.

- Cost: 3D printing can be expensive, particularly for high-end technologies, such as SLS.

Future Directions

Despite the challenges and limitations, printable rover tech has the potential to revolutionize space exploration. Future directions for this technology include:

- Advancements in materials: Developing new materials with improved strength and durability.

- Advancements in printing technologies: Improving the speed and accuracy of 3D printing technologies.

- Increased adoption: Increasing the adoption of printable rover tech in space exploration missions.

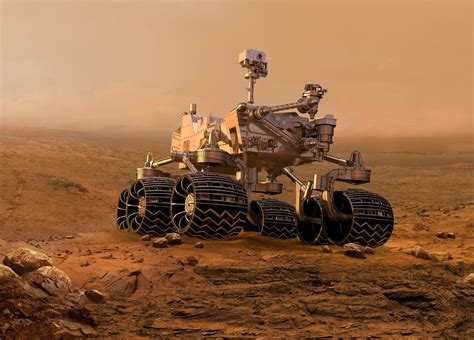

Gallery of Printable Rover Tech

FAQs

What is printable rover tech?

+Printable rover tech refers to the use of 3D printing and other additive manufacturing techniques to create rover components.

What are the benefits of printable rover tech?

+Printable rover tech offers several benefits, including reduced weight, increased customization, faster production, and cost-effectiveness.

What are the challenges and limitations of printable rover tech?

+Printable rover tech faces several challenges and limitations, including material limitations, scalability, and cost.

In conclusion, printable rover tech has the potential to revolutionize space exploration by providing a faster, more cost-effective, and more customizable way of producing rover components. As the technology continues to advance, we can expect to see increased adoption in space exploration missions.