As a 3D printing enthusiast, you're likely no stranger to the thrill of working with resin-based materials. Siraya Tech's Fast Resin is a popular choice among hobbyists and professionals alike, thanks to its exceptional printing quality and ease of use. However, getting the most out of this versatile resin requires a bit of know-how. In this article, we'll dive into seven essential tips for optimizing your Siraya Tech Fast Resin settings for stunning results.

Understanding the Basics of Siraya Tech Fast Resin

Before we dive into the nitty-gritty of optimizing your resin settings, let's take a brief look at what makes Siraya Tech's Fast Resin so special. This fast-curing resin is designed to produce prints with exceptional detail and accuracy, making it an ideal choice for a wide range of applications, from miniature models to dental and jewelry designs.

Tips for Optimizing Your Siraya Tech Fast Resin Settings

1. Calibrate Your Printer

To get the most out of your Siraya Tech Fast Resin, it's essential to ensure your 3D printer is properly calibrated. This includes leveling the build plate, adjusting the z-axis, and fine-tuning the extruder settings. A well-calibrated printer will help prevent issues like layer shifting, warping, and poor adhesion.

2. Choose the Right Layer Thickness

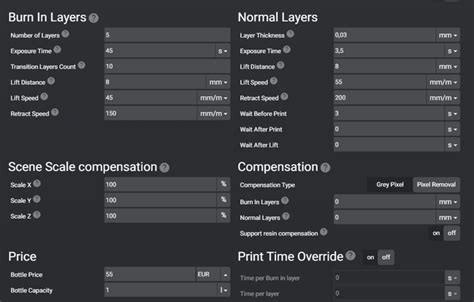

Siraya Tech's Fast Resin is designed to work well with a range of layer thicknesses, but finding the optimal setting for your specific print can make a significant difference in terms of quality and speed. As a general rule, thicker layers (0.05-0.1mm) are best suited for larger prints, while thinner layers (0.01-0.05mm) are ideal for smaller, more detailed models.

3. Adjust Your Exposure Time

The exposure time of your resin printer's UV light can have a significant impact on the quality of your prints. If the exposure time is too short, the resin may not fully cure, leading to a weak or brittle finish. On the other hand, over-exposure can cause the resin to become too hard or even yellow. Experiment with different exposure times to find the sweet spot for your specific print.

4. Experiment with Infill Densities

Infill density refers to the amount of material used to fill the interior of a print. A higher infill density can add strength and stability to your print, but it can also increase printing time and material usage. Experiment with different infill densities to find the perfect balance between strength and efficiency.

5. Pay Attention to Support Settings

Siraya Tech's Fast Resin is designed to work well with a range of support settings, but finding the optimal configuration can make a significant difference in terms of print quality and removal. Experiment with different support densities, angles, and patterns to find the best approach for your specific print.

6. Keep Your Workspace Clean and Organized

A clean and organized workspace is essential for achieving consistent results with your Siraya Tech Fast Resin. Make sure to store your resin in a cool, dry place, and avoid exposing it to direct sunlight or moisture. Regularly clean your printer and workspace to prevent contamination and ensure optimal performance.

7. Post-Curing for Enhanced Quality

Post-curing is the process of exposing your printed model to additional UV light after the initial print is complete. This can help to enhance the quality and durability of your print, as well as improve its overall appearance. Experiment with different post-curing times and techniques to find the best approach for your specific print.

Conclusion: Optimizing Your Siraya Tech Fast Resin Settings for Success

By following these seven tips, you can unlock the full potential of your Siraya Tech Fast Resin and achieve stunning results with your 3D prints. Remember to always calibrate your printer, choose the right layer thickness, adjust your exposure time, experiment with infill densities, pay attention to support settings, keep your workspace clean and organized, and post-cure your prints for enhanced quality.

Gallery of Siraya Tech Fast Resin Prints

What is the ideal layer thickness for Siraya Tech Fast Resin?

+The ideal layer thickness for Siraya Tech Fast Resin depends on the specific print and desired level of detail. As a general rule, thicker layers (0.05-0.1mm) are best suited for larger prints, while thinner layers (0.01-0.05mm) are ideal for smaller, more detailed models.

How do I calibrate my 3D printer for Siraya Tech Fast Resin?

+To calibrate your 3D printer for Siraya Tech Fast Resin, start by leveling the build plate and adjusting the z-axis. Then, fine-tune the extruder settings and ensure the printer is properly aligned. Refer to your printer's user manual for specific calibration instructions.

What is the recommended exposure time for Siraya Tech Fast Resin?

+The recommended exposure time for Siraya Tech Fast Resin depends on the specific print and desired level of curing. As a general rule, start with a shorter exposure time (10-20 seconds) and adjust as needed to achieve the desired level of curing.