Lenze AC Tech drives are widely used in various industrial applications, and like any complex device, they can sometimes experience faults. Understanding these faults and their corresponding codes is crucial for efficient troubleshooting and maintenance. In this article, we will delve into the world of Lenze AC Tech drive fault codes, explaining their meanings and providing insights into how to address them.

The Importance of Understanding Fault Codes

Fault codes are predefined indicators used by the drive's control system to communicate specific issues or errors. These codes can be displayed on the drive's control panel, logged in the drive's memory, or even communicated to a centralized control system. By understanding the meaning behind these codes, operators and maintenance personnel can quickly identify problems, minimizing downtime and reducing the risk of further damage.

Classification of Fault Codes

Lenze AC Tech drive fault codes can be broadly classified into several categories, each representing a specific type of issue:

- Hardware Faults: These codes indicate problems with the drive's physical components, such as power electronic failures, temperature issues, or communication errors.

- Software Faults: These codes relate to issues with the drive's software or firmware, including programming errors, configuration problems, or data corruption.

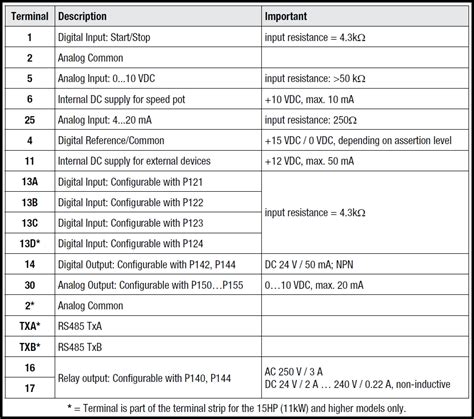

- I/O Faults: These codes are associated with issues related to input/output operations, such as faulty sensors, incorrect wiring, or communication errors.

- Application Faults: These codes indicate problems with the application or process being controlled by the drive, such as overcurrent, undervoltage, or mechanical issues.

Common Lenze AC Tech Drive Fault Codes

Here are some common fault codes encountered in Lenze AC Tech drives, along with their meanings and possible causes:

Hardware Faults

- Fault Code 101: Power electronic failure

- Possible cause: Overcurrent, overheating, or manufacturing defect

- Action: Check the drive's power electronic components, such as IGBTs or diodes, and replace if necessary

- Fault Code 102: Temperature error

- Possible cause: Overheating due to poor cooling, high ambient temperature, or malfunctioning cooling system

- Action: Check the drive's cooling system, ensure proper airflow, and verify that the temperature sensor is functioning correctly

Software Faults

- Fault Code 201: Programming error

- Possible cause: Incorrect programming, corrupted data, or incompatible software version

- Action: Verify that the programming is correct, check for data corruption, and update the software to the latest version if necessary

- Fault Code 202: Configuration error

- Possible cause: Incorrect configuration, mismatched parameters, or incompatible hardware

- Action: Check the drive's configuration, verify that parameters are set correctly, and ensure that the hardware is compatible

I/O Faults

- Fault Code 301: Communication error

- Possible cause: Faulty communication cable, incorrect communication settings, or malfunctioning communication module

- Action: Check the communication cable, verify that communication settings are correct, and replace the communication module if necessary

- Fault Code 302: Sensor fault

- Possible cause: Faulty sensor, incorrect sensor configuration, or sensor wiring issue

- Action: Check the sensor, verify that the sensor configuration is correct, and inspect the sensor wiring for any issues

Application Faults

- Fault Code 401: Overcurrent

- Possible cause: Excessive load, incorrect motor sizing, or malfunctioning motor

- Action: Check the load, verify that the motor is sized correctly, and inspect the motor for any issues

- Fault Code 402: Undervoltage

- Possible cause: Low input voltage, incorrect voltage settings, or malfunctioning voltage regulator

- Action: Check the input voltage, verify that voltage settings are correct, and inspect the voltage regulator for any issues

Troubleshooting and Maintenance

To minimize downtime and prevent further damage, it is essential to have a structured approach to troubleshooting and maintenance. Here are some general steps to follow:

- Identify the Fault Code: Check the drive's control panel or logs to determine the specific fault code.

- Consult the Manual: Refer to the drive's manual or documentation to understand the meaning behind the fault code.

- Gather Information: Collect relevant data, such as the drive's configuration, operating conditions, and any recent changes.

- Analyze the Data: Analyze the data to identify potential causes and narrow down the problem.

- Perform Maintenance: Perform routine maintenance tasks, such as cleaning, inspecting, and replacing components as needed.

- Test and Verify: Test the drive to verify that the issue is resolved and that the drive is functioning correctly.

Gallery of Lenze AC Tech Drive Fault Codes

FAQs

What is a fault code in a Lenze AC Tech drive?

+A fault code is a predefined indicator used by the drive's control system to communicate specific issues or errors.

How do I troubleshoot a Lenze AC Tech drive fault code?

+Identify the fault code, consult the manual, gather information, analyze the data, perform maintenance, and test and verify the drive.

What is the importance of understanding fault codes in Lenze AC Tech drives?

+Understanding fault codes helps minimize downtime, prevents further damage, and ensures efficient troubleshooting and maintenance.

By understanding Lenze AC Tech drive fault codes, operators and maintenance personnel can quickly identify problems, reducing downtime and minimizing the risk of further damage. Regular maintenance and troubleshooting can help prevent faults from occurring in the first place, ensuring that the drive operates at optimal levels. If you have any questions or need further assistance, please don't hesitate to comment below.