The rapidly evolving field of semiconductor manufacturing has been witnessing significant advancements in recent years. One such innovation that has been gaining attention is Strip Tech, a revolutionary approach to wafer processing. This cutting-edge technology has the potential to transform the way we produce semiconductors, making it faster, more efficient, and cost-effective. In this article, we will delve into the world of Strip Tech, exploring its benefits, working mechanisms, and the impact it can have on the future of wafer processing.

What is Strip Tech?

Strip Tech, also known as "strip processing" or "batch strip," is a novel wafer processing technique that involves the simultaneous processing of multiple wafers in a single batch. Unlike traditional batch processing, where wafers are processed individually, Strip Tech enables the treatment of multiple wafers as a single unit, resulting in increased throughput and reduced processing time.

Benefits of Strip Tech

The advantages of Strip Tech are numerous, making it an attractive solution for semiconductor manufacturers. Some of the key benefits include:

- Increased Throughput: By processing multiple wafers at once, Strip Tech significantly boosts production rates, allowing manufacturers to meet growing demand for semiconductors.

- Improved Efficiency: Strip Tech reduces the number of processing steps required, minimizing the risk of human error and increasing overall efficiency.

- Cost Savings: By processing wafers in bulk, manufacturers can reduce costs associated with labor, equipment, and maintenance.

- Enhanced Uniformity: Strip Tech enables uniform processing of multiple wafers, resulting in improved consistency and reduced variability.

How Does Strip Tech Work?

The Strip Tech process involves several key steps:

- Wafer Preparation: Multiple wafers are prepared for processing by cleaning and aligning them in a specialized carrier.

- Batch Loading: The prepared wafers are loaded into a processing chamber, where they are treated as a single unit.

- Processing: The wafers undergo various processing steps, such as etching, deposition, or implantation, in a controlled environment.

- Unloading: After processing, the wafers are unloaded from the chamber and prepared for further processing or packaging.

Applications of Strip Tech

Strip Tech has far-reaching implications for various industries, including:

- Semiconductor Manufacturing: Strip Tech can be used for a wide range of semiconductor processing applications, from front-end to back-end processing.

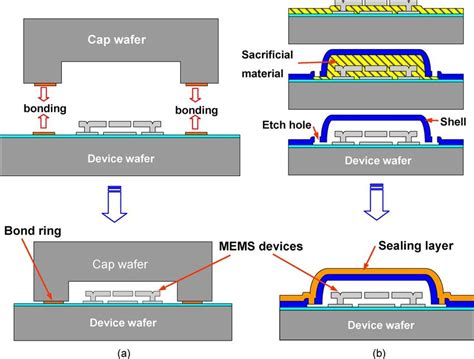

- MEMS and NEMS: The technology is particularly well-suited for the production of microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS).

- LED and Display Manufacturing: Strip Tech can be used for the production of light-emitting diodes (LEDs) and display devices, such as OLEDs and LCDs.

Challenges and Limitations

While Strip Tech offers numerous benefits, there are also challenges and limitations to consider:

- Scalability: As the technology is still in its infancy, scaling up to larger wafer sizes and higher volumes can be a challenge.

- Uniformity: Maintaining uniform processing conditions across multiple wafers can be difficult, potentially affecting yield and quality.

- Equipment Costs: The specialized equipment required for Strip Tech can be expensive, making it a significant investment for manufacturers.

Future of Wafer Processing

As the demand for semiconductors continues to grow, the need for innovative processing techniques like Strip Tech becomes increasingly important. The future of wafer processing is likely to be shaped by advancements in Strip Tech, enabling manufacturers to produce high-quality semiconductors more efficiently and cost-effectively.

Gallery of Strip Tech Images

FAQs

What is Strip Tech?

+Strip Tech is a novel wafer processing technique that involves the simultaneous processing of multiple wafers in a single batch.

What are the benefits of Strip Tech?

+The benefits of Strip Tech include increased throughput, improved efficiency, cost savings, and enhanced uniformity.

What are the applications of Strip Tech?

+Strip Tech can be used for a wide range of semiconductor processing applications, including front-end to back-end processing, MEMS and NEMS production, and LED and display manufacturing.

As we conclude our exploration of Strip Tech, it is clear that this innovative technology has the potential to revolutionize the field of wafer processing. With its numerous benefits, including increased throughput, improved efficiency, and cost savings, Strip Tech is poised to play a significant role in shaping the future of semiconductor manufacturing. We invite you to share your thoughts on the potential applications and implications of Strip Tech in the comments below.