Transformers have been a staple of modern electrical power systems for over a century. Their ability to efficiently transmit and distribute electrical energy across vast distances has made them an indispensable component of the global power infrastructure. However, with the rise of renewable energy sources and the increasing demand for high-voltage direct current (HVDC) transmission systems, the technology behind transformers has undergone significant changes in recent years. As a result, understanding the latest Transformers tech specs has become more crucial than ever for engineers, researchers, and industry professionals. In this article, we will delve into five essential Transformers tech specs that you need to know.

Understanding Transformers Efficiency

Transformers efficiency is a critical parameter that determines the overall performance of the device. It is defined as the ratio of the output power to the input power and is usually expressed as a percentage. Modern transformers are designed to operate at high efficiency levels, typically in the range of 95% to 99%. However, achieving such high efficiency levels requires careful consideration of various factors, including the design of the magnetic core, the type of winding material used, and the operating temperature.

Factors Affecting Transformers Efficiency

Several factors can affect the efficiency of a transformer, including:

- Core losses: These are losses that occur due to the magnetic core and can be minimized by using high-quality core materials and optimizing the core design.

- Copper losses: These are losses that occur due to the resistance of the winding material and can be minimized by using low-resistance materials and optimizing the winding design.

- Operating temperature: High operating temperatures can reduce the efficiency of a transformer, so it's essential to ensure that the device is operated within the recommended temperature range.

Transformers Cooling Systems

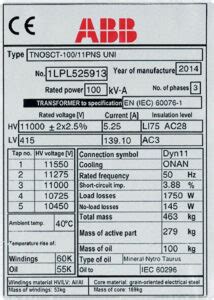

Transformers cooling systems are designed to remove heat generated by the device during operation. There are several types of cooling systems available, including air-cooled, water-cooled, and oil-cooled systems. The choice of cooling system depends on the specific application and the operating conditions of the transformer.

Types of Cooling Systems

- Air-cooled systems: These systems use air to cool the transformer and are typically used for small to medium-sized devices.

- Water-cooled systems: These systems use water to cool the transformer and are typically used for large devices or devices that operate in high-temperature environments.

- Oil-cooled systems: These systems use oil to cool the transformer and are typically used for devices that operate in high-voltage applications.

Transformers Insulation Systems

Transformers insulation systems are designed to prevent electrical discharges and ensure safe operation of the device. There are several types of insulation systems available, including solid insulation, liquid insulation, and gas insulation.

Types of Insulation Systems

- Solid insulation: This type of insulation uses solid materials, such as paper or plastic, to insulate the transformer.

- Liquid insulation: This type of insulation uses liquids, such as oil or water, to insulate the transformer.

- Gas insulation: This type of insulation uses gases, such as sulfur hexafluoride (SF6), to insulate the transformer.

Transformers Protection Systems

Transformers protection systems are designed to protect the device from electrical faults and ensure safe operation. There are several types of protection systems available, including overcurrent protection, overvoltage protection, and surge protection.

Types of Protection Systems

- Overcurrent protection: This type of protection system detects overcurrent conditions and trips the circuit breaker to prevent damage to the transformer.

- Overvoltage protection: This type of protection system detects overvoltage conditions and reduces the voltage to prevent damage to the transformer.

- Surge protection: This type of protection system detects surge conditions and absorbs the surge energy to prevent damage to the transformer.

Transformers Monitoring Systems

Transformers monitoring systems are designed to monitor the condition of the device in real-time and detect potential faults before they occur. There are several types of monitoring systems available, including temperature monitoring, vibration monitoring, and partial discharge monitoring.

Types of Monitoring Systems

- Temperature monitoring: This type of monitoring system measures the temperature of the transformer and detects overheating conditions.

- Vibration monitoring: This type of monitoring system measures the vibration of the transformer and detects abnormal vibration conditions.

- Partial discharge monitoring: This type of monitoring system detects partial discharges in the transformer and alerts the operator to potential faults.

What is the purpose of a transformer?

+The purpose of a transformer is to increase or decrease the voltage of an alternating current (AC) electrical signal.

What are the types of transformers?

+There are several types of transformers, including step-up transformers, step-down transformers, and isolation transformers.

How do transformers work?

+Transformers work by using the principle of electromagnetic induction to transfer energy from one circuit to another.

We hope this article has provided you with a comprehensive understanding of the essential Transformers tech specs. Whether you're an engineer, researcher, or industry professional, knowing these specs is crucial for designing, building, and operating efficient and reliable transformers. Remember to share your thoughts and questions in the comments section below, and don't forget to follow us for more informative articles on electrical engineering and technology.